Holiday Test

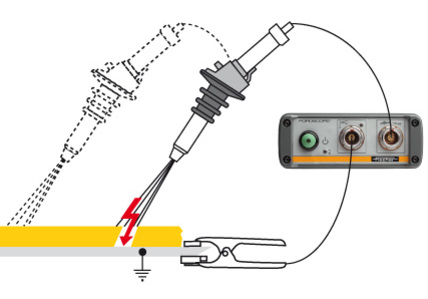

Holiday Testing is a non-destructive method used to discover unacceptable discontinuities that compromise the integrity of linings, such as pinholes and voids, in protective coatings. The test involves examining an electric circuit to determine if the coating is insufficient to resist the electrical charge and current flows required to complete the circuit. If the electrical current is detected, it indicates the presence of a pinhole or a break in the insulation (discontinuity). Testing throughout the holidays is often known as continuity testing.

A holiday detector is an electrical device used to perform the holiday test above- mentioned. There are different strategies and technology available for holiday detection. Depending on the coating thickness, it can be achieved by applying low voltage or high voltage across the chosen path. When the thickness of the coating system is less than 500 microns (20 mils), low-voltage holiday testing is utilized. This is normally accomplished using a wet sponge. When the coating system is thicker and includes a device producing a high voltage discharge, high-voltage holiday testing is utilized. Special precautions must be taken during high-voltage holiday testing to avoid damaging the coating or injuring the operator.

Advantages

Lets Get in Touch!

Call us

+609-8582168

Email us

admin@nde-group.com